Avoid collisions with previous extrusions in the same layer when moving Z down in an XYZ move.

This happens for example when starting a scarf joint after another perimeter was already printed.

Fixes SoftFever#7191

Co-authored-by: SoftFever <softfeverever@gmail.com>

* Add BLOCKS RD50, ProS100 and RF50 printers

Add printer configurations and profiles for Blockstech printers to OrcaSlicer

* Update RF50 thumbnail

Added the definative thumbnail for the RF50 printer model.

* pa calib: print flow value and acceleration

Print flow value and acceleration for PA pattern calibration.

This should help keep track during adaptive PA calibration.

* pa pattern: fix legent section too wide in some cases

Rework pa pattern legent generation to correctly estimate

width of the legend section.

Current flow value now has variable length which is a longest of

PA value and the acceleration for a given test.

Few examples:

1. PA value are 4 characters: 0.04

Acceleratioion 3 chars: 400

Flow value will be 4 chars long: 7.98, or 11.3

2. PA: 0.018

Accel: 1000

Flow: 12.35, or 6.345

3. PA: 0.04

Accel: 15000

Flow: 34.34, or 4.567

Rework number-to-string conversion flow to correctly round values at

given precision.

Fixed Clipper library (our own fork of it) when working with Z coordinate:

The Eigen vector type compares all components, while the ClipperLib

own IntPoint type compared x and y only.

Fixed by overriding the ==/!= operators to compare just x and y components

for Eigen types.

Cherry-picked from prusa3d/PrusaSlicer@0202eec4b7

Co-authored-by: Vojtech Bubnik <bubnikv@gmail.com>

If layer starts with a color change, the full layer time will be much longer, which will trick the slicer to think this layer has enough cooling time.

However the actual filament extrusion time (the real "printing" part) won't necessarily have enough time to cool down, so if we don't do extra slowing down

before starting next layer, the filament could still be soft and lead to worse surface quality.

# Description

Re-Creation of Pull Request #6964 with X1E changes pulled.

OrcaSlicer includes exhaust fan settings for each filaments, however

these settings do not take effect on Bambu Labs machines that include

chamber temperature regulation fans.

Further investigation into the g-code files produced reveals that the

filament start g-code is responsible for using the air filtration

setting and sending the appropriate `M106 P3

S{during_print_exhaust_fan_speed_num[current_extruder]}` command to the

printer. However, this command, even with the setting enabled, is never

written to the final g-code file.

By default, Bambu Lab's filament profiles wrap this command up in` {if

activate_air_filtration[current_extruder] && support_air_filtration}`

clause, which always evaluates to false. As it turns out, the printer's

have the `support_air_filtration` flag set to `0` in the

`fdm_machine_common.json` file.

This change updates that value to `1` in the .json files for the X1,

X1C, X1E, and P1S 0.4mm nozzles. This is then inherited to other nozzle

sizes and user generated profiles. This is done by simply adding a line

` "support_air_filtration": "1",` to the .json to override the inherited

setting.

<!--

> Please provide a summary of the changes made in this PR. Include

details such as:

> * What issue does this PR address or fix?

> * What new features or enhancements does this PR introduce?

> * Are there any breaking changes or dependencies that need to be

considered?

-->

Fixes#6066

# Screenshots/Recordings/Graphs

N/A

## Tests

Updated this flag in a custom user config for the printer than tried

generating the code file with Air Filtration enabled and set to 70%

The appropriate `M106 P3 S178 ` appears in the filament start gcode

section of the file.

<!--

> Please provide a summary of the changes made in this PR. Include

details such as:

> * What issue does this PR address or fix?

> * What new features or enhancements does this PR introduce?

> * Are there any breaking changes or dependencies that need to be

considered?

-->

# Screenshots/Recordings/Graphs

<!--

> Please attach relevant screenshots to showcase the UI changes.

> Please attach images that can help explain the changes.

-->

## Tests

Updated this flag in a custom user config for the printer than tried

generating the code file with Air Filtration enabled and set to 70%

The appropriate `M106 P3 S178 ` appears in the filament start gcode

section of the file.

# Description

Added support for Creality Print (E.g. Orca can upload and print

directly to Ender 3 V3 KE)

# Screenshots/Recordings/Graphs

Video: https://www.youtube.com/watch?v=ONzaMJhj_Hk

## Tests

Tested in the video above on a Macbook Pro, Ender 3 V3 KE.

It should also be tested on Windows but I don't have a windows computer.

# Description

fixed#6987

# Screenshots/Recordings/Graphs

<!--

> Please attach relevant screenshots to showcase the UI changes.

> Please attach images that can help explain the changes.

-->

## Tests

<!--

> Please describe the tests that you have conducted to verify the

changes made in this PR.

-->

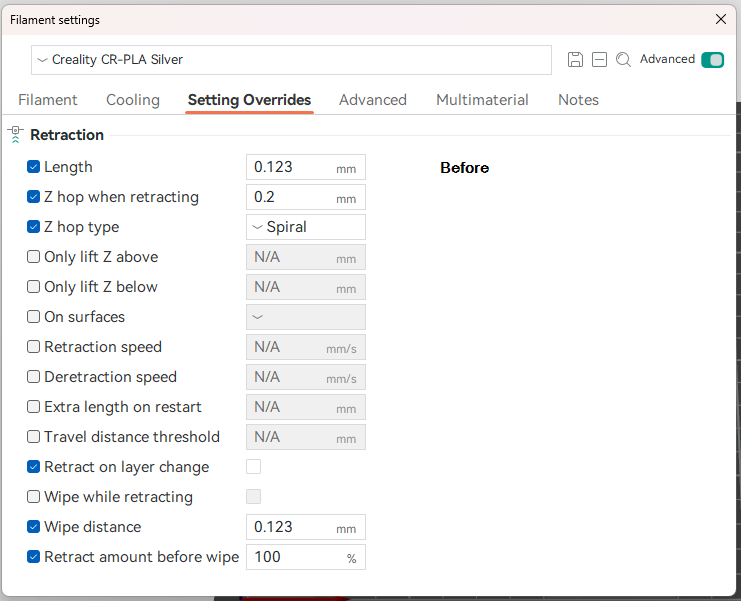

# Description

The idea behind this PR is to make it easier for the users to tweak

filament setting overrides i.e. reduce number of times users have to

switch between the printer and filament settings to compare the values.

# Screenshots/Recordings/Graphs

## Tests

I've done some manual testing to confirm:

* Override setting with the same value as extruder is still shown as a

change.

* Resetting unsaved override setting back to original value still works

as expected.

* Override settings are shown correctly on the next load after a save.

* Extruder settings changes are reflected on Settings Overrides page.

## Other

I have discovered a strange behaviour between `Filament Settings` and

`Printer Settings` windows. On a fresh load of application opening

`Filament Settings` window, navigating to `Settings Overrides` tab and

then closing the window results in `Filament` tab being opened the next

time `Filament Settings` window is opened. But if you open `Printer

settings` window, navigate to `Extruder` or `Motion ability` tabs then

the application changes the behaviour to open the last visited tab by

the user for both of the windows. I'm mentioning this because when this

happens the flow of events in the application changes and causes my

change to break until the user changes a tab. As far as I can tell for

some reason ConfigOptionsGroup's `reload_config` method is starting to

get called (second time?) after TabFilament's

`update_filament_overrides_page` method which wipes out the values set

by me. I'm not sure which is the correct behaviour, so I left that for a

discussion here. If last visited tab is the correct behaviour, then I

would need help to figure out how to fix this problem.