parent

809e6d1cc7

commit

90601c098a

11 changed files with 100 additions and 65 deletions

|

|

@ -3,5 +3,5 @@ Welcome to the OrcaSlicer WIKI!

|

|||

We have divided it roughly into the following pages:

|

||||

|

||||

* [Calibration](wiki/Calibration)

|

||||

* [Seam](wiki/Seam)

|

||||

* [Print settings](wiki/Print-settings/Home)

|

||||

* [How to build Orca Slicer](wiki/How-to-build)

|

||||

|

|

|

|||

6

doc/Print-settings/Home.md

Normal file

6

doc/Print-settings/Home.md

Normal file

|

|

@ -0,0 +1,6 @@

|

|||

Print settings:

|

||||

|

||||

* [Seam](wiki/Print-settings/Seam)

|

||||

* [Axiliary fan](wiki/Print-settings/auxiliary-fan)

|

||||

* [Chamber temperature](wiki/Print-settings/chamber-temperature)

|

||||

* [Air filtration](wiki/Print-settings/air-filtration)

|

||||

|

|

@ -1,17 +1,17 @@

|

|||

WIP...

|

||||

|

||||

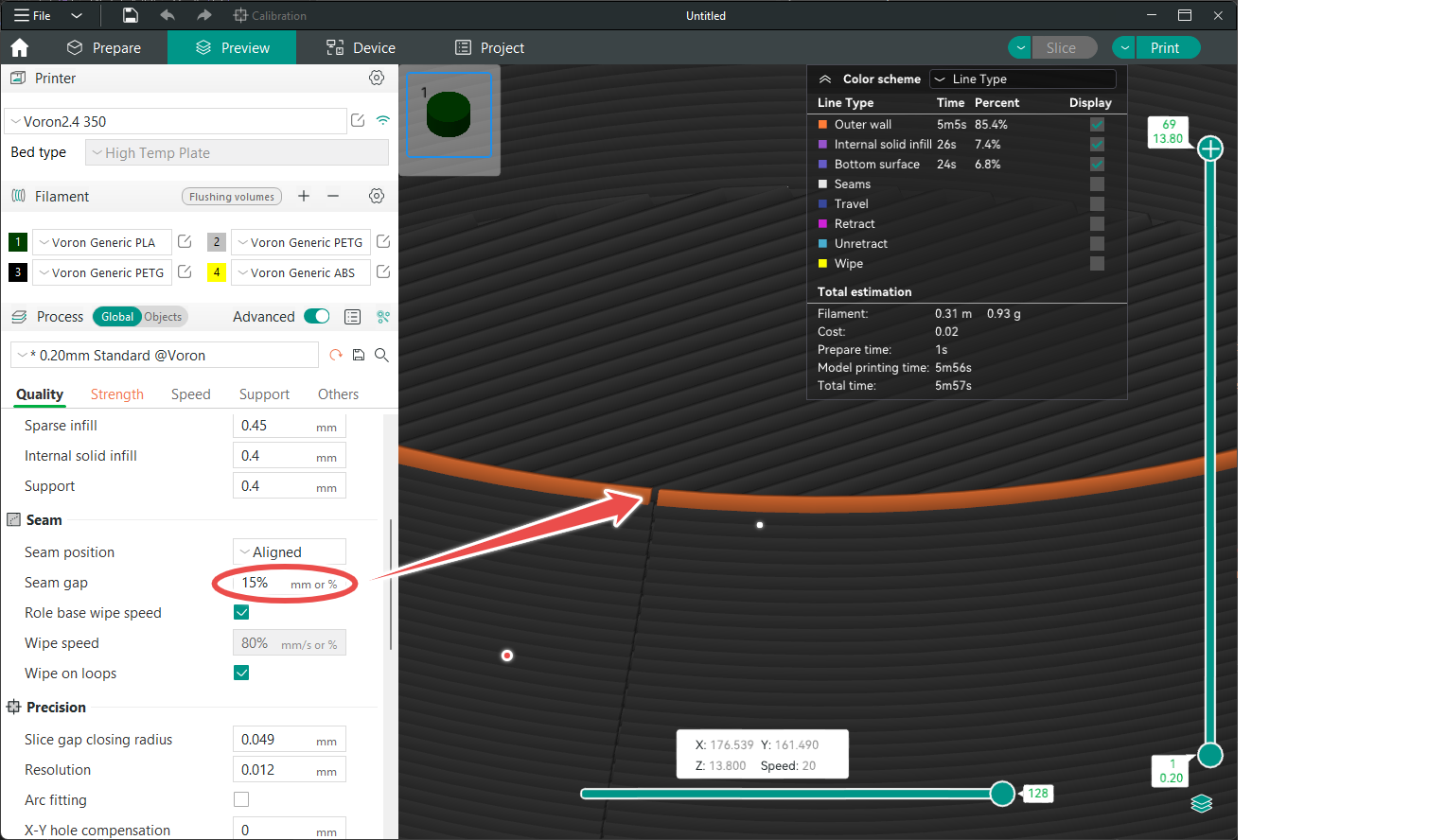

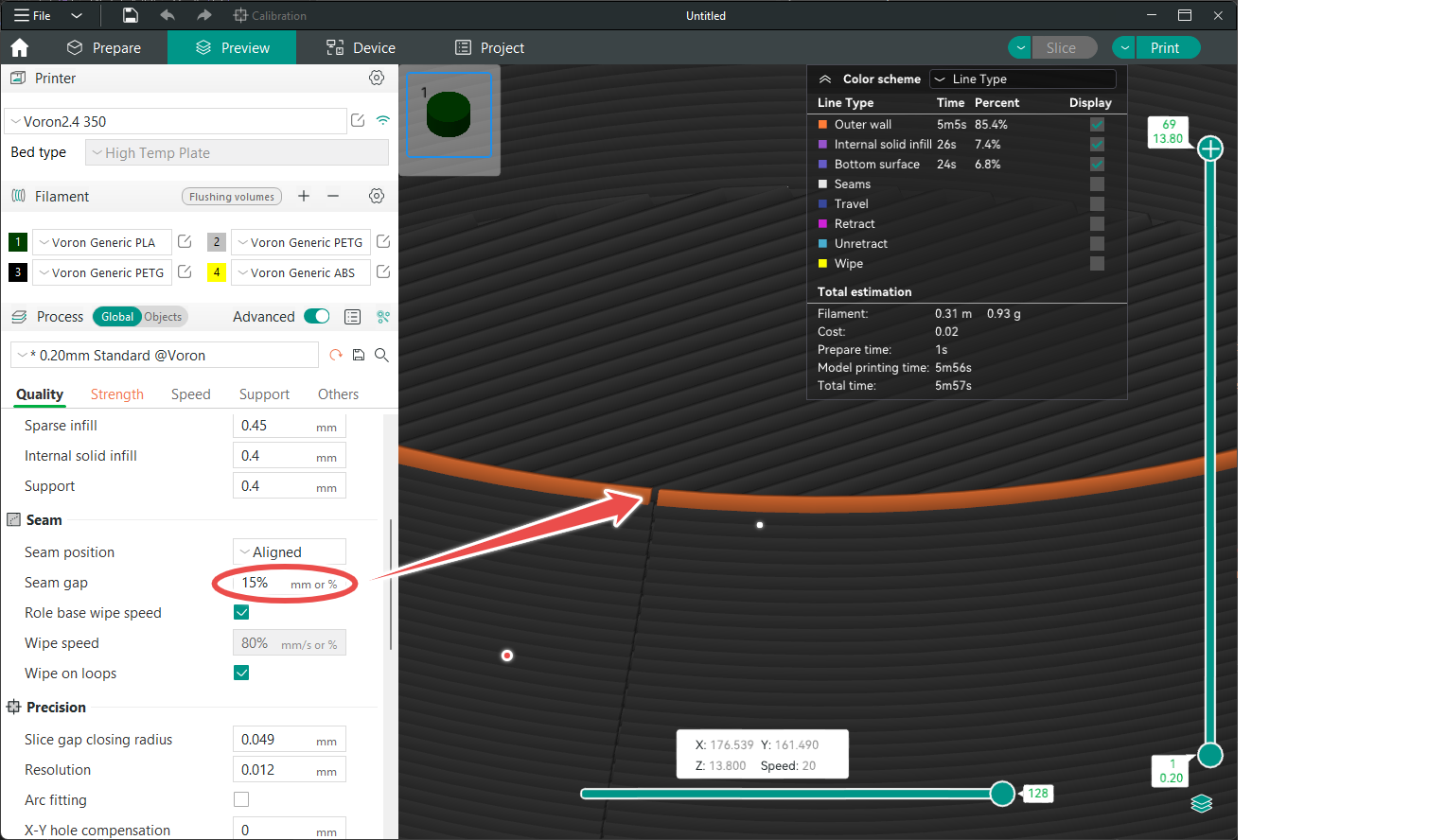

### Seam gap

|

||||

|

||||

|

||||

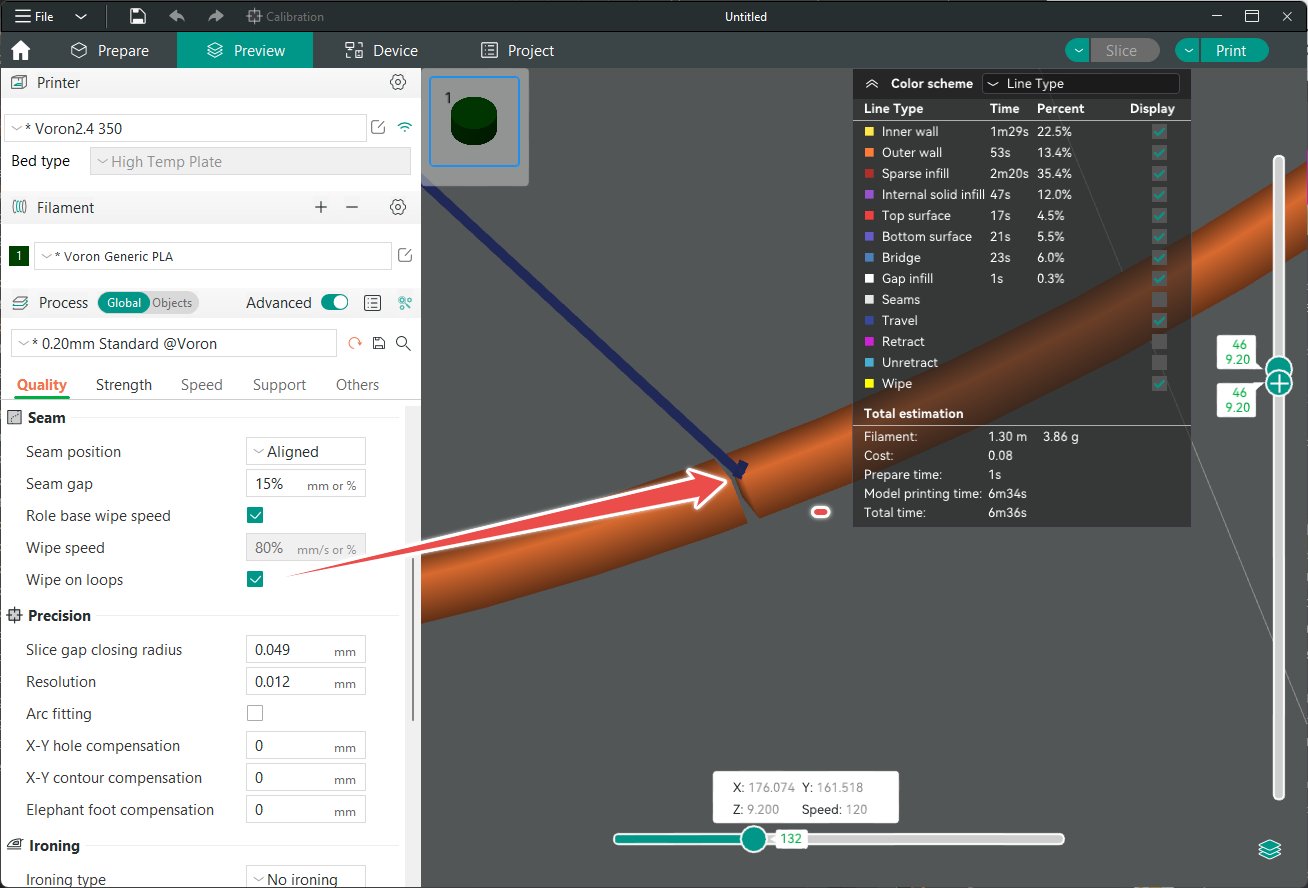

### Role-based wipe speed(auto)

|

||||

### Wipe speed

|

||||

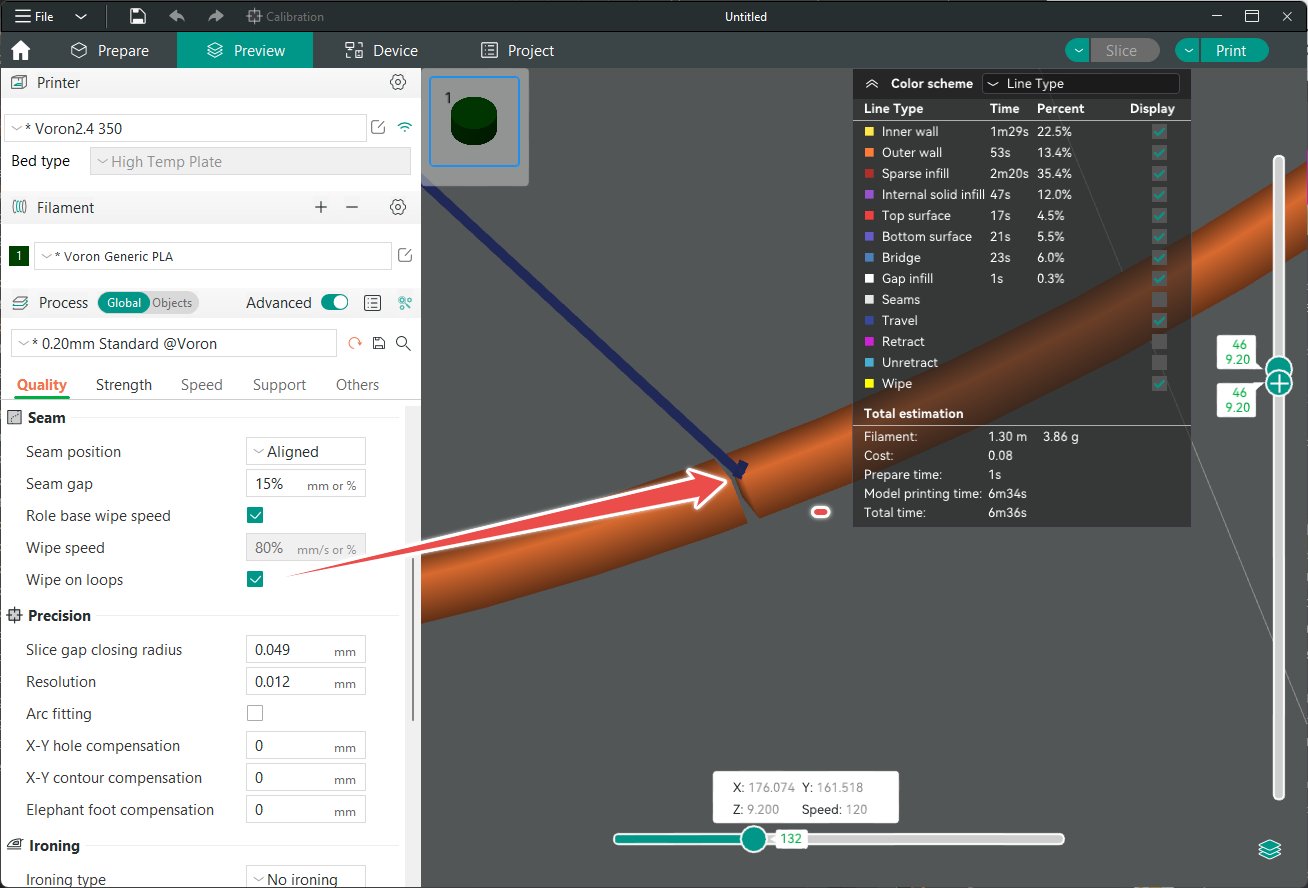

### Wipe on loop(inward movement)

|

||||

|

||||

|

||||

Use outer wall speed and acceleration instead of travel speed and acceleration.

|

||||

Added an option to disable this feature

|

||||

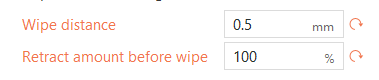

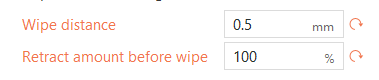

### Support Cura style outer wall wipe(100% retract before wipe)

|

||||

|

||||

|

||||

|

||||

WIP...

|

||||

|

||||

### Seam gap

|

||||

|

||||

|

||||

### Role-based wipe speed(auto)

|

||||

### Wipe speed

|

||||

### Wipe on loop(inward movement)

|

||||

|

||||

|

||||

Use outer wall speed and acceleration instead of travel speed and acceleration.

|

||||

Added an option to disable this feature

|

||||

### Support Cura style outer wall wipe(100% retract before wipe)

|

||||

|

||||

|

||||

|

||||

Extra length on restart

|

||||

6

resources/images/param_chamber_temp.svg

Normal file

6

resources/images/param_chamber_temp.svg

Normal file

|

|

@ -0,0 +1,6 @@

|

|||

<svg width="16" height="16" viewBox="0 0 16 16" fill="none" xmlns="http://www.w3.org/2000/svg">

|

||||

<path d="M4.74539 2C4.74539 2.80568 3.11719 2.80568 3.11719 3.60976C3.11719 4.41544 4.74539 4.41544 4.74539 5.22111C4.74539 6.02679 3.11719 6.02679 3.11719 6.83247C3.11719 7.63815 4.74539 7.63815 4.74539 8.44382C4.74539 9.2495 3.11719 9.2495 3.11719 10.0552" stroke="#6B6B6B" stroke-miterlimit="10" stroke-linecap="round"/>

|

||||

<path d="M9.12039 2C9.12039 2.80568 7.49219 2.80568 7.49219 3.60976C7.49219 4.41544 9.12039 4.41544 9.12039 5.22111C9.12039 6.02679 7.49219 6.02679 7.49219 6.83247C7.49219 7.63815 9.12039 7.63815 9.12039 8.44382C9.12039 9.2495 7.49219 9.2495 7.49219 10.0552" stroke="#6B6B6B" stroke-miterlimit="10" stroke-linecap="round"/>

|

||||

<path d="M13.4969 2C13.4969 2.80568 11.8687 2.80568 11.8687 3.60976C11.8687 4.41544 13.4969 4.41544 13.4969 5.22111C13.4969 6.02679 11.8687 6.02679 11.8687 6.83247C11.8687 7.63815 13.4969 7.63815 13.4969 8.44382C13.4969 9.2495 11.8687 9.2495 11.8687 10.0552" stroke="#6B6B6B" stroke-miterlimit="10" stroke-linecap="round"/>

|

||||

<rect x="2.5" y="12.1055" width="11.8627" height="1.8816" rx="0.9408" stroke="#6B6B6B"/>

|

||||

</svg>

|

||||

|

After Width: | Height: | Size: 1.1 KiB |

|

|

@ -2240,6 +2240,17 @@ void GCode::_do_export(Print& print, GCodeOutputStream &file, ThumbnailsGenerato

|

|||

// adds tag for processor

|

||||

file.write_format(";%s%s\n", GCodeProcessor::reserved_tag(GCodeProcessor::ETags::Role).c_str(), ExtrusionEntity::role_to_string(erCustom).c_str());

|

||||

|

||||

// Orca: set chamber temperature at the beginning of gcode file

|

||||

bool activate_chamber_temp_control = false;

|

||||

auto max_chamber_temp = 0;

|

||||

for (const auto &extruder : m_writer.extruders()) {

|

||||

activate_chamber_temp_control |= m_config.activate_chamber_temp_control.get_at(extruder.id());

|

||||

max_chamber_temp = std::max(max_chamber_temp, m_config.chamber_temperature.get_at(extruder.id()));

|

||||

}

|

||||

|

||||

if (activate_chamber_temp_control && max_chamber_temp > 0)

|

||||

file.write(m_writer.set_chamber_temperature(max_chamber_temp, true)); // set chamber_temperature

|

||||

|

||||

// Write the custom start G-code

|

||||

file.writeln(machine_start_gcode);

|

||||

|

||||

|

|

@ -2262,10 +2273,19 @@ void GCode::_do_export(Print& print, GCodeOutputStream &file, ThumbnailsGenerato

|

|||

*/

|

||||

if (is_bbl_printers) {

|

||||

this->_print_first_layer_extruder_temperatures(file, print, machine_start_gcode, initial_extruder_id, true);

|

||||

if (m_config.support_air_filtration.getBool() && m_config.activate_air_filtration.get_at(initial_extruder_id)) {

|

||||

file.write(m_writer.set_exhaust_fan(m_config.during_print_exhaust_fan_speed.get_at(initial_extruder_id), true));

|

||||

}

|

||||

}

|

||||

// Orca: when activate_air_filtration is set on any extruder, find and set the highest during_print_exhaust_fan_speed

|

||||

bool activate_air_filtration = false;

|

||||

int during_print_exhaust_fan_speed = 0;

|

||||

for (const auto &extruder : m_writer.extruders()) {

|

||||

activate_air_filtration |= m_config.activate_air_filtration.get_at(extruder.id());

|

||||

if (m_config.activate_air_filtration.get_at(extruder.id()))

|

||||

during_print_exhaust_fan_speed = std::max(during_print_exhaust_fan_speed,

|

||||

m_config.during_print_exhaust_fan_speed.get_at(extruder.id()));

|

||||

}

|

||||

if (activate_air_filtration)

|

||||

file.write(m_writer.set_exhaust_fan(during_print_exhaust_fan_speed, true));

|

||||

|

||||

print.throw_if_canceled();

|

||||

|

||||

// Set other general things.

|

||||

|

|

@ -2528,10 +2548,16 @@ void GCode::_do_export(Print& print, GCodeOutputStream &file, ThumbnailsGenerato

|

|||

file.write(m_writer.update_progress(m_layer_count, m_layer_count, true)); // 100%

|

||||

file.write(m_writer.postamble());

|

||||

|

||||

if (print.config().support_chamber_temp_control.value || print.config().chamber_temperature.values[0] > 0)

|

||||

if (activate_chamber_temp_control && max_chamber_temp > 0)

|

||||

file.write(m_writer.set_chamber_temperature(0, false)); //close chamber_temperature

|

||||

|

||||

|

||||

if (activate_air_filtration) {

|

||||

int complete_print_exhaust_fan_speed = 0;

|

||||

for (const auto& extruder : m_writer.extruders())

|

||||

if (m_config.activate_air_filtration.get_at(extruder.id()))

|

||||

complete_print_exhaust_fan_speed = std::max(complete_print_exhaust_fan_speed, m_config.complete_print_exhaust_fan_speed.get_at(extruder.id()));

|

||||

file.write(m_writer.set_exhaust_fan(complete_print_exhaust_fan_speed, true));

|

||||

}

|

||||

// adds tags for time estimators

|

||||

file.write_format(";%s\n", GCodeProcessor::reserved_tag(GCodeProcessor::ETags::Last_Line_M73_Placeholder).c_str());

|

||||

file.write_format("; EXECUTABLE_BLOCK_END\n\n");

|

||||

|

|

@ -2581,19 +2607,6 @@ void GCode::_do_export(Print& print, GCodeOutputStream &file, ThumbnailsGenerato

|

|||

}

|

||||

file.write("\n");

|

||||

|

||||

bool activate_air_filtration = false;

|

||||

for (const auto& extruder : m_writer.extruders())

|

||||

activate_air_filtration |= m_config.activate_air_filtration.get_at(extruder.id());

|

||||

activate_air_filtration &= m_config.support_air_filtration.getBool();

|

||||

|

||||

if (activate_air_filtration) {

|

||||

int complete_print_exhaust_fan_speed = 0;

|

||||

for (const auto& extruder : m_writer.extruders())

|

||||

if (m_config.activate_air_filtration.get_at(extruder.id()))

|

||||

complete_print_exhaust_fan_speed = std::max(complete_print_exhaust_fan_speed, m_config.complete_print_exhaust_fan_speed.get_at(extruder.id()));

|

||||

file.write(m_writer.set_exhaust_fan(complete_print_exhaust_fan_speed, true));

|

||||

}

|

||||

|

||||

print.throw_if_canceled();

|

||||

}

|

||||

|

||||

|

|

|

|||

|

|

@ -164,9 +164,13 @@ std::string GCodeWriter::set_chamber_temperature(int temperature, bool wait)

|

|||

|

||||

if (wait)

|

||||

{

|

||||

gcode<<"M106 P2 S255 \n";

|

||||

gcode<<"M191 S"<<std::to_string(temperature)<<" ;"<<"set chamber_temperature and wait for it to be reached\n";

|

||||

gcode<<"M106 P2 S0 \n";

|

||||

// Orca: should we let the M191 command to turn on the auxiliary fan?

|

||||

if (config.auxiliary_fan)

|

||||

gcode << "M106 P2 S255 \n";

|

||||

gcode << "M191 S" << std::to_string(temperature) << " ;"

|

||||

<< "set chamber_temperature and wait for it to be reached\n";

|

||||

if (config.auxiliary_fan)

|

||||

gcode << "M106 P2 S0 \n";

|

||||

}

|

||||

else {

|

||||

code = "M141";

|

||||

|

|

|

|||

|

|

@ -803,8 +803,8 @@ static std::vector<std::string> s_Preset_filament_options {

|

|||

"filament_loading_speed", "filament_loading_speed_start", "filament_load_time",

|

||||

"filament_unloading_speed", "filament_unloading_speed_start", "filament_unload_time", "filament_toolchange_delay", "filament_cooling_moves",

|

||||

"filament_cooling_initial_speed", "filament_cooling_final_speed", "filament_ramming_parameters",

|

||||

"filament_multitool_ramming", "filament_multitool_ramming_volume", "filament_multitool_ramming_flow",

|

||||

};

|

||||

"filament_multitool_ramming", "filament_multitool_ramming_volume", "filament_multitool_ramming_flow", "activate_chamber_temp_control"

|

||||

};

|

||||

|

||||

static std::vector<std::string> s_Preset_machine_limits_options {

|

||||

"machine_max_acceleration_extruding", "machine_max_acceleration_retracting", "machine_max_acceleration_travel",

|

||||

|

|

|

|||

|

|

@ -1108,7 +1108,7 @@ void PrintConfigDef::init_fff_params()

|

|||

|

||||

def = this->add("activate_air_filtration",coBools);

|

||||

def->label = L("Activate air filtration");

|

||||

def->tooltip = L("Activate for better air filtration");

|

||||

def->tooltip = L("Activate for better air filtration. G-code command: M106 P3 S(0-255)");

|

||||

def->mode = comSimple;

|

||||

def->set_default_value(new ConfigOptionBools{false});

|

||||

|

||||

|

|

@ -2173,7 +2173,7 @@ def = this->add("filament_loading_speed", coFloats);

|

|||

|

||||

def = this->add("auxiliary_fan", coBool);

|

||||

def->label = L("Auxiliary part cooling fan");

|

||||

def->tooltip = L("Enable this option if machine has auxiliary part cooling fan");

|

||||

def->tooltip = L("Enable this option if machine has auxiliary part cooling fan. G-code command: M106 P2 S(0-255).");

|

||||

def->mode = comAdvanced;

|

||||

def->set_default_value(new ConfigOptionBool(false));

|

||||

|

||||

|

|

@ -2217,18 +2217,19 @@ def = this->add("filament_loading_speed", coFloats);

|

|||

def->mode = comAdvanced;

|

||||

def->set_default_value(new ConfigOptionFloat(0));

|

||||

|

||||

// Orca: may remove this option later

|

||||

def =this->add("support_chamber_temp_control",coBool);

|

||||

def->label=L("Support control chamber temperature");

|

||||

def->tooltip=L("This option is enabled if machine support controlling chamber temperature");

|

||||

def->tooltip=L("This option is enabled if machine support controlling chamber temperature\nG-code command: M141 S(0-255)");

|

||||

def->mode=comDevelop;

|

||||

def->set_default_value(new ConfigOptionBool(false));

|

||||

def->set_default_value(new ConfigOptionBool(true));

|

||||

def->readonly=false;

|

||||

|

||||

def =this->add("support_air_filtration",coBool);

|

||||

def->label=L("Support air filtration");

|

||||

def->tooltip=L("Enable this if printer support air filtration");

|

||||

def->tooltip=L("Enable this if printer support air filtration\nG-code command: M106 P3 S(0-255)");

|

||||

def->mode=comDevelop;

|

||||

def->set_default_value(new ConfigOptionBool(false));

|

||||

def->set_default_value(new ConfigOptionBool(true));

|

||||

|

||||

def = this->add("gcode_flavor", coEnum);

|

||||

def->label = L("G-code flavor");

|

||||

|

|

@ -2661,7 +2662,7 @@ def = this->add("filament_loading_speed", coFloats);

|

|||

def = this->add("additional_cooling_fan_speed", coInts);

|

||||

def->label = L("Fan speed");

|

||||

def->tooltip = L("Speed of auxiliary part cooling fan. Auxiliary fan will run at this speed during printing except the first several layers "

|

||||

"which is defined by no cooling layers");

|

||||

"which is defined by no cooling layers.\nPlease enable auxiliary_fan in printer settings to use this feature. G-code command: M106 P2 S(0-255)");

|

||||

def->sidetext = L("%");

|

||||

def->min = 0;

|

||||

def->max = 100;

|

||||

|

|

@ -3897,6 +3898,12 @@ def = this->add("filament_loading_speed", coFloats);

|

|||

def->mode = comAdvanced;

|

||||

def->set_default_value(new ConfigOptionBool(false));

|

||||

|

||||

def = this->add("activate_chamber_temp_control",coBools);

|

||||

def->label = L("Activate temperature control");

|

||||

def->tooltip = L("Enable this option for chamber temperature control. An M191 command will be added before \"machine_start_gcode\"\nG-code commands: M141/M191 S(0-255)");

|

||||

def->mode = comSimple;

|

||||

def->set_default_value(new ConfigOptionBools{false});

|

||||

|

||||

def = this->add("chamber_temperature", coInts);

|

||||

def->label = L("Chamber temperature");

|

||||

def->tooltip = L("Higher chamber temperature can help suppress or reduce warping and potentially lead to higher interlayer bonding strength for high temperature materials like ABS, ASA, PC, PA and so on."

|

||||

|

|

|

|||

|

|

@ -1087,7 +1087,6 @@ PRINT_CONFIG_CLASS_DERIVED_DEFINE(

|

|||

((ConfigOptionBool, spiral_mode))

|

||||

((ConfigOptionInt, standby_temperature_delta))

|

||||

((ConfigOptionInts, nozzle_temperature))

|

||||

((ConfigOptionInts , chamber_temperature))

|

||||

((ConfigOptionBools, wipe))

|

||||

// BBS

|

||||

((ConfigOptionInts, nozzle_temperature_range_low))

|

||||

|

|

@ -1137,6 +1136,9 @@ PRINT_CONFIG_CLASS_DERIVED_DEFINE(

|

|||

((ConfigOptionString, notes))

|

||||

((ConfigOptionString, printer_notes))

|

||||

|

||||

((ConfigOptionBools, activate_chamber_temp_control))

|

||||

((ConfigOptionInts , chamber_temperature))

|

||||

|

||||

|

||||

|

||||

)

|

||||

|

|

|

|||

|

|

@ -1250,14 +1250,9 @@ wxString OptionsGroup::get_url(const std::string& path_end)

|

|||

anchor.Replace(L" ", "-");

|

||||

str = str.Left(pos) + anchor;

|

||||

}

|

||||

// Softfever: point to sf wiki for seam parameters

|

||||

if (path_end == "Seam") {

|

||||

return wxString::Format(L"https://github.com/SoftFever/OrcaSlicer/wiki/%s", from_u8(path_end));

|

||||

}

|

||||

else {

|

||||

//BBS

|

||||

return wxString::Format(L"https://wiki.bambulab.com/%s/software/bambu-studio/%s", L"en", str);

|

||||

}

|

||||

// Orca: point to sf wiki for seam parameters

|

||||

return wxString::Format(L"https://github.com/SoftFever/OrcaSlicer/wiki/Print-settings/%s", from_u8(path_end));

|

||||

|

||||

}

|

||||

|

||||

bool OptionsGroup::launch_browser(const std::string& path_end)

|

||||

|

|

|

|||

|

|

@ -2725,11 +2725,14 @@ void TabFilament::build()

|

|||

optgroup->append_line(line);

|

||||

|

||||

|

||||

optgroup = page->new_optgroup(L("Print temperature"), L"param_temperature");

|

||||

optgroup->append_single_option_line("chamber_temperature","chamber-temperature");

|

||||

optgroup = page->new_optgroup(L("Print chamber temperature"), L"param_chamber_temp");

|

||||

optgroup->append_single_option_line("chamber_temperature", "chamber-temperature");

|

||||

optgroup->append_single_option_line("activate_chamber_temp_control", "chamber-temperature");

|

||||

|

||||

optgroup->append_separator();

|

||||

|

||||

|

||||

optgroup = page->new_optgroup(L("Print temperature"), L"param_temperature");

|

||||

line = { L("Nozzle"), L("Nozzle temperature when printing") };

|

||||

line.append_option(optgroup->get_option("nozzle_temperature_initial_layer"));

|

||||

line.append_option(optgroup->get_option("nozzle_temperature"));

|

||||

|

|

@ -2829,11 +2832,11 @@ void TabFilament::build()

|

|||

optgroup->append_single_option_line("support_material_interface_fan_speed");

|

||||

|

||||

optgroup = page->new_optgroup(L("Auxiliary part cooling fan"), L"param_cooling_fan");

|

||||

optgroup->append_single_option_line("additional_cooling_fan_speed");

|

||||

optgroup->append_single_option_line("additional_cooling_fan_speed", "auxiliary-fan");

|

||||

|

||||

optgroup = page->new_optgroup(L("Exhaust fan"),L"param_cooling_fan");

|

||||

|

||||

optgroup->append_single_option_line("activate_air_filtration");

|

||||

optgroup->append_single_option_line("activate_air_filtration", "air-filtration");

|

||||

|

||||

line = {L("During print"), ""};

|

||||

line.append_option(optgroup->get_option("during_print_exhaust_fan_speed"));

|

||||

|

|

@ -3004,8 +3007,7 @@ void TabFilament::toggle_options()

|

|||

toggle_line("cool_plate_temp_initial_layer", is_BBL_printer);

|

||||

toggle_line("eng_plate_temp_initial_layer", is_BBL_printer);

|

||||

toggle_line("textured_plate_temp_initial_layer", is_BBL_printer);

|

||||

// bool support_chamber_temp_control = this->m_preset_bundle->printers.get_selected_preset().config.opt_bool("support_chamber_temp_control");

|

||||

// toggle_option("chamber_temperature", !is_BBL_printer || support_chamber_temp_control);

|

||||

|

||||

}

|

||||

if (m_active_page->title() == L("Setting Overrides"))

|

||||

update_filament_overrides_page();

|

||||

|

|

@ -3166,9 +3168,9 @@ void TabPrinter::build_fff()

|

|||

optgroup = page->new_optgroup(L("Accessory") /*, L"param_accessory"*/);

|

||||

optgroup->append_single_option_line("nozzle_type");

|

||||

optgroup->append_single_option_line("nozzle_hrc");

|

||||

optgroup->append_single_option_line("auxiliary_fan");

|

||||

optgroup->append_single_option_line("support_chamber_temp_control");

|

||||

optgroup->append_single_option_line("support_air_filtration");

|

||||

optgroup->append_single_option_line("auxiliary_fan", "auxiliary-fan");

|

||||

optgroup->append_single_option_line("support_chamber_temp_control", "chamber-temperature");

|

||||

optgroup->append_single_option_line("support_air_filtration", "air-filtration");

|

||||

|

||||

const int gcode_field_height = 15; // 150

|

||||

const int notes_field_height = 25; // 250

|

||||

|

|

|

|||

Loading…

Reference in a new issue